H20 Beam for Formwork

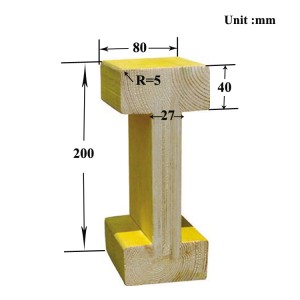

1.Size:200mm(Height)x80mm(Width)x40mm(Flange Thickness)x27mm(Web Thickness)

2.Length: 1.9-5.9m

3.Flange: Sawed Pine, Spruce

4.Web: Birch, Poplar, Larch Plywood

5.Glue: WBP

6.Surface: Coated by Antiseptic and Waterproof Yellow Painting

Detail of the H20 Beam

Light Weight: the density of H20 Formwork Timber H20 Wood Pine Beam is only 4.8-5.0 kg per meter, it is easy to deliver, dismantle and install.

High Tenacity: The Formwork H20 Timber H20 Wood Pine Beam is not easy to break off because of fiber.

Good Proofing: The Formwork H20 Timber H20 Wood Pine Beam is good at waterproof, acid proofing, alkali proofing, moth proofing, and corrosion resistance.

Environment Friendly: The Formwork H20 Timber H20 Wood Pine Beam belongs to renewable resources, could be used many time. And without poison, no damage to health.

Good Straightness: The Formwork H20 Timber H20 Wood Pine Beam in not easy to deform.

Advantages

I-beam is an important part of the international common building formwork system. It has the characteristics of light weight, high strength, good straightness, not easy to deformation, water and acid and alkali resistance on the surface. It can be used year-round and has low cost amortization costs. Can be used with domestic and foreign professional template system products.

2, can be widely used in horizontal formwork system, vertical formwork system (wall mold, column mold, hydraulic climbing mold, etc.), variable arc formwork system and heterosexual formwork and other formwork system.

3, woodworking beam straight wall template for loading and unloading template, convenient assembly, in a certain range and degree can be assembled into a variety of sizes of templates, flexible application. Mold plate stiffness, length and height are very convenient, the maximum of a template can be poured more than 10 meters. Because of the light quality of the template material, the whole template is much lighter than the steel template when assembled.

4, the system product parts high degree of standardization, good reuse, meet the requirements of environmental protection.