OEM Manufacturer Hpl Plywood - CDX Pine Plywood for Structural Roofing & Sub-floor – Dongstar

OEM Manufacturer Hpl Plywood - CDX Pine Plywood for Structural Roofing & Sub-floor – Dongstar Detail:

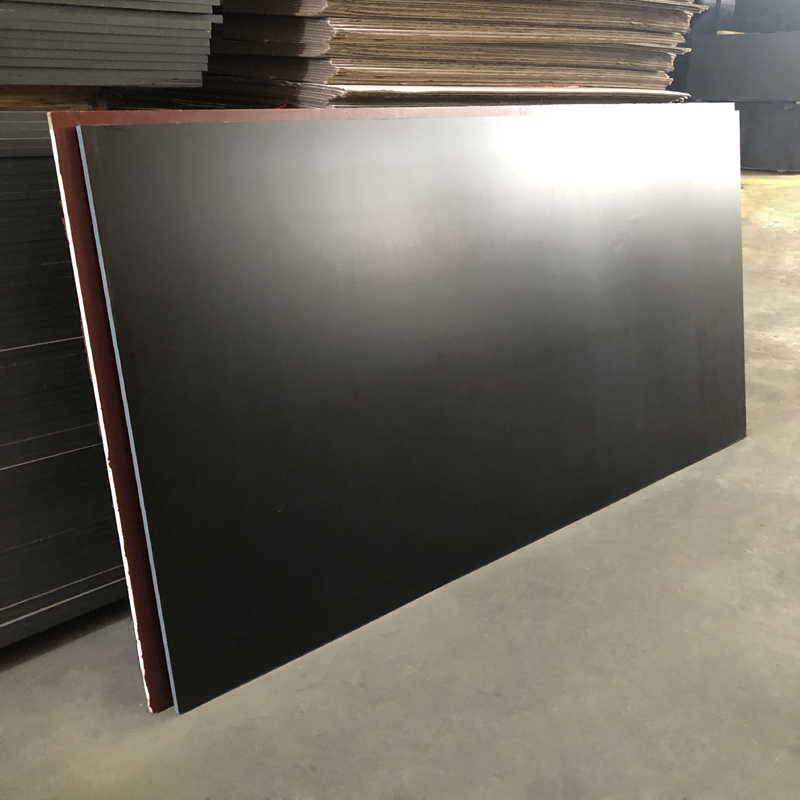

| Name | 18mm 3/4” CDX Pine Plywood |

| Size | 1220x2440mm,1250x2500mm ,or as Customized |

| Thickness | 6mm~30mm |

| Face/Back | Pine (or spruce ) |

| Core Material | Eucalyptus,Poplar,Combi core,Pine or as request |

| Grade | C/D or BB/CC |

| Glue | Phenolic,WBP Melamine,MR,E0,E1,E2 |

| Glue emission level | E0, E1, E2 |

| Surface Treatment | Polished/Non-Polished |

| Density | 500-750kg/m3 |

| Moisture Content | 8%~14% |

| Usage | Construction,Packing,Sub-Flooring ,Roofing , Wall Exterior ,Structural ,etc |

| Certification | FSC,CE,EUTR,CARB,EPA |

Phenolic Glue meets Weatherproof bonding according to EN 314-2/Class 3, outdoor. meets emission class E1 in EN 13986 on low formaldehyde emission, German ChemVerbotsV – so-called emission class E05 / M1 emission classification / French VOC regulation A+.

Pine surface, relatively compact, oily so good waterproof, elasticity and air permeability, good thermal conductivity, pine growth cycle is long, fine rings, wood texture flexible, the tree oil content is low, and its color distribution is uniform.CDX is the best-selling grade of pine plywood.It can be used in furniture manufacturing, concrete pouring and other different scenes.

Pine Plywood Thickness ::2.0mm-30mm ( 2.0mm / 2.4mm / 2.7mm / 3.2mm / 3.6mm / 4mm / 5.2mm / 5.5mm / 6mm / 9mm / 12mm / 15mm / 18mm / 21mm-30mm or 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 9/16″, 5/8″, 11/16″, 3/4″, 13/16″, 7/8″, 15/16″, 1″ )

Advantages :

1. Wear resistance, crack resistance, acid and alkali resistance.

2. No color pollution between the concrete and the plate.

3. It can be cut into small pieces and reused.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for OEM Manufacturer Hpl Plywood - CDX Pine Plywood for Structural Roofing & Sub-floor – Dongstar , The product will supply to all over the world, such as: Iran, Surabaya, Belarus, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.