If you’ve ever walked through a hardware store or scrolled through a home renovation forum, you’ve probably seen the word “plywood” pop up more than once. But beyond being a staple on job sites, what exactly is plywood used for—and why does it remain one of the most trusted materials in construction and design?

Whether you’re a contractor managing a commercial build, a weekend warrior tackling a garage workshop project, or a designer sourcing sustainable materials, understanding plywood’s versatility can save you time, money, and headaches.

Let’s break it down—no fluff, just practical insight.

Why Plywood? Strength, Flexibility, and Value

Plywood is an engineered wood product made by gluing together thin layers (or “plies”) of wood veneer, with each layer rotated 90 degrees from the one below. This cross-grain construction gives plywood its signature strength, dimensional stability, and resistance to warping—making it far more reliable than solid wood in many applications.

Top Uses of Plywood in Real Projects

1. Structural Sheathing & Framing

In residential and commercial construction, plywood is a go-to for wall sheathing, roof decking, and subfloors. Its load-bearing capacity and nail-holding strength make it ideal for framing support. Many builders prefer it over OSB (oriented strand board) in high-moisture areas due to better swelling resistance.

Pro Tip: Use CDX plywood (C-grade front, D-grade back, exterior glue) for outdoor structural work—it’s budget-friendly and code-compliant.

2. Cabinetry & Built-In Furniture

From kitchen cabinets to closet organizers, cabinet-grade plywood (like birch or maple) offers a smooth surface that accepts paint and stain beautifully. Unlike particleboard, it won’t sag under weight or crack at joints.

3. Exterior Siding & Outdoor Structures

When treated or made with waterproof adhesives (like in marine plywood), plywood can handle decks, sheds, and even garden planters. While not as weatherproof as metal or fiber cement, it’s lightweight and easy to cut on-site.

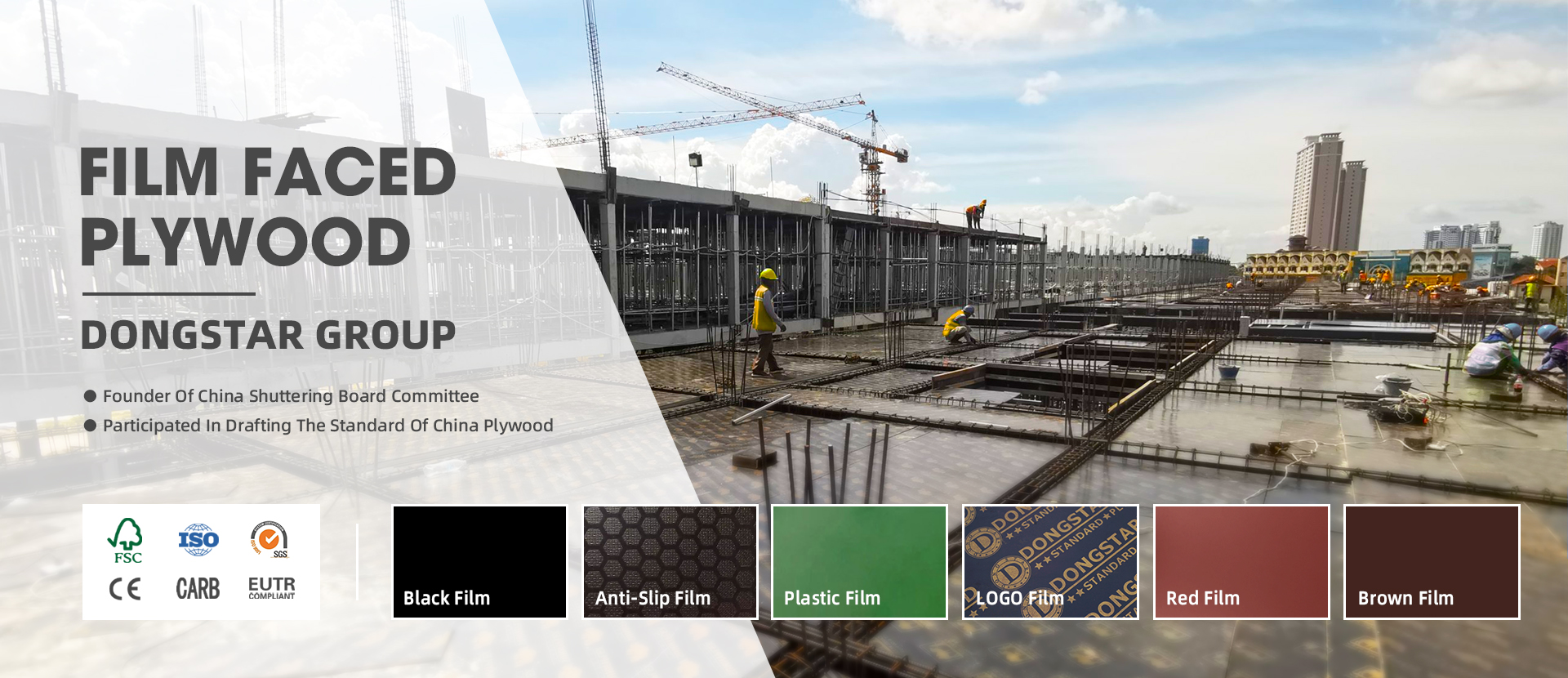

4. Temporary Formwork for Concrete

Contractors rely on plywood for concrete formwork because it’s flat, reusable, and holds shape under pressure. Film-faced plywood is especially popular—it creates a smooth concrete finish and can be reused dozens of times.

5. Creative & Decorative Applications

Think beyond structure: designers are using plywood for wall paneling, retail displays, modern shelving, and even art installations. Its natural grain and eco-friendly profile (many brands now use FSC-certified wood) align with today’s demand for authentic, low-impact materials.

Choosing the Right Plywood: Don’t Guess—Know

Not all plywood is created equal. Here’s a quick reference:

| Type | Best For | Key Feature |

| Softwood Plywood | Framing, sheathing, roofing | Affordable, strong, widely available |

| Hardwood Plywood | Cabinets, furniture, doors | Smooth finish, durable edges |

| Marine Plywood | Boats, outdoor wet areas | Waterproof glue, void-free core |

| Baltic Birch | CNC projects, jigs, drawer boxes | Consistent plies, no filler |

Always check the exposure rating (Interior, Exterior, or Structural I) and grade stamp before buying.

The Bottom Line

Plywood isn’t just “cheap wood.” It’s a smart, adaptable material that bridges performance and practicality. With rising costs of solid lumber and growing interest in modular, efficient builds, plywood’s role is only expanding.

So next time you’re planning a project—big or small—ask yourself: Could plywood make this faster, stronger, or more sustainable? Chances are, the answer is yes.

Post time: Jan-22-2026